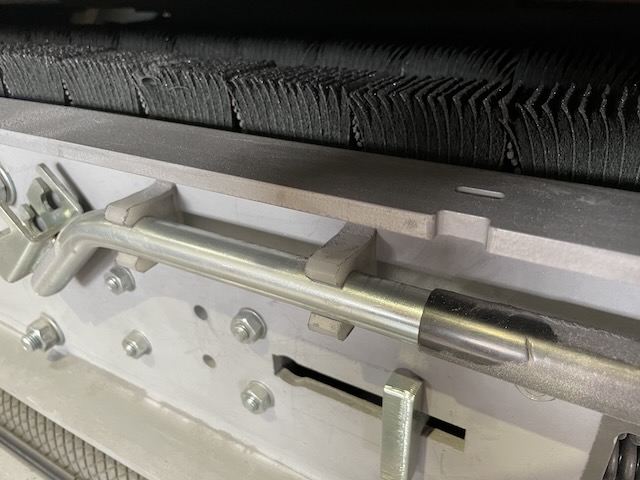

Lissmac SBM-S 1000

| max. working width | 1000 mm |

|---|---|

| workable material thickness | 20 mm |

| Tension | 400 V / 50 Hz |

| Total power | 28,5 A |

| Total current consumption | 12,6 kW |

| Insulation class | IP54 |

| Infinitely variable feed speed | 0-4 m / min |

| Length | 2230 mm |

| Width | 1500 mm |

| Height | 1532 mm |

| Machine weight | 1700 kg |

| Serial number | |

|---|---|

| Construction year | 2007 |

Standard features

- adjustment of material thickness: fully variable / manual

- adjustment of tools: fully variable / manual

Additional equipment

- including exhaust unit Ries 330 D

Description

Lissmac innovative systems for metal processing set high standards for metal finishing. Their unique method of simultaneously deburring edges on inside and outside contours of steel, stainless steel, or laser cut parts on both sides in one single pass is highly efficient. Compared to conventional deburring machines Lissmac saves processing times of up to 60%.

Features and Benefits – Deburring machine SBM-S

· Deburring and edge rounding of sheet and plate up to 20 mm material thickness

· No need to turn sheets over and running them through the machine again

· Highest quality during subsequent processing or finishing

· Simultaneous processing of all inside and outside edges

· Even and slow wear of consumables

· No damage to the parent metal – tolerances remain intact

· Will even deburr sheet covered in protective film without damaging the film

· Belt surface equal to 7,5 sq m of abrasive material – few tool changes

· Dry operation – no water, sludge or complex drying process

· Infinitely variable feed speed

· Easy and safe operation with minimal maintenance

· Compact and modular construction – less space needed

· The operation of all Lissmac grinding, deburring, and edge rounding machines can be linked and sequenced together with innovative conveyor systems and combined single controls